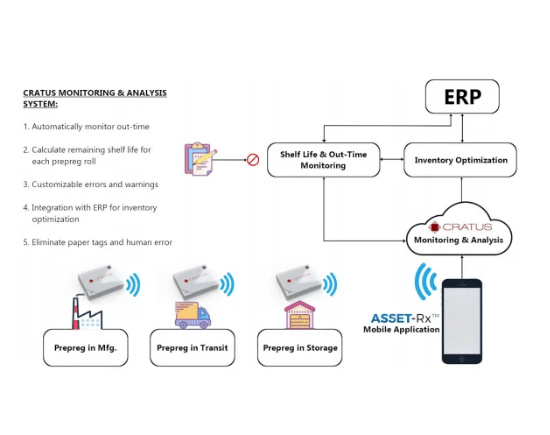

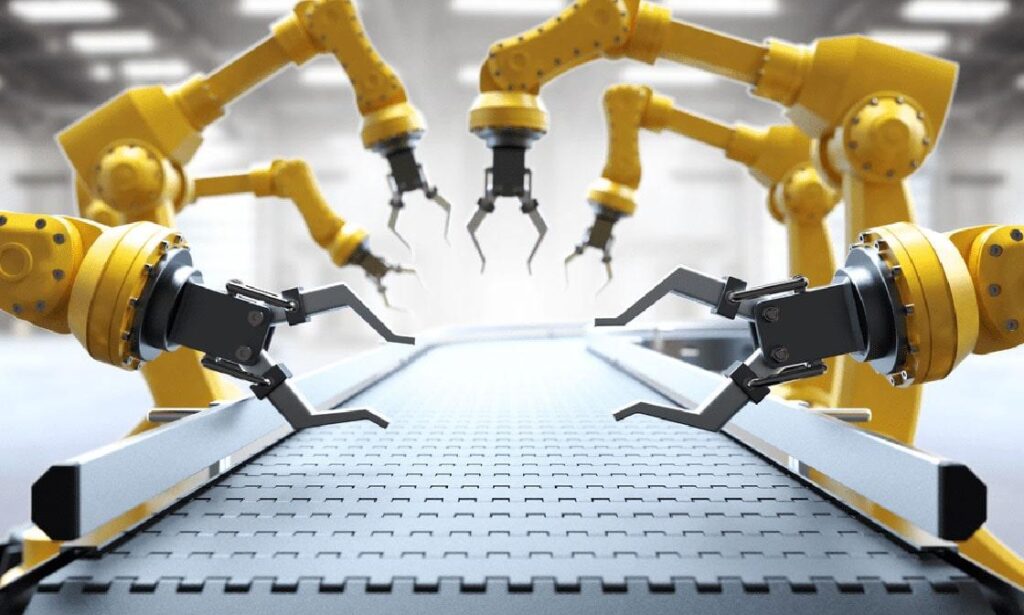

Real-time location data is the key element of what digital transformation brings to the table in any setting. Today’s visibility solutions help streamline operations by optimizing valuable resources such as assets and equipment, real estate, workforce, and inventory. ASSET-Rx RTLS solutions make it easy to locate key assets, people, inventory. Beyond presenting raw location data, ASSET-Rx extracts analytics and statistical information on your selected KPIs which matter to you and your operation the most.