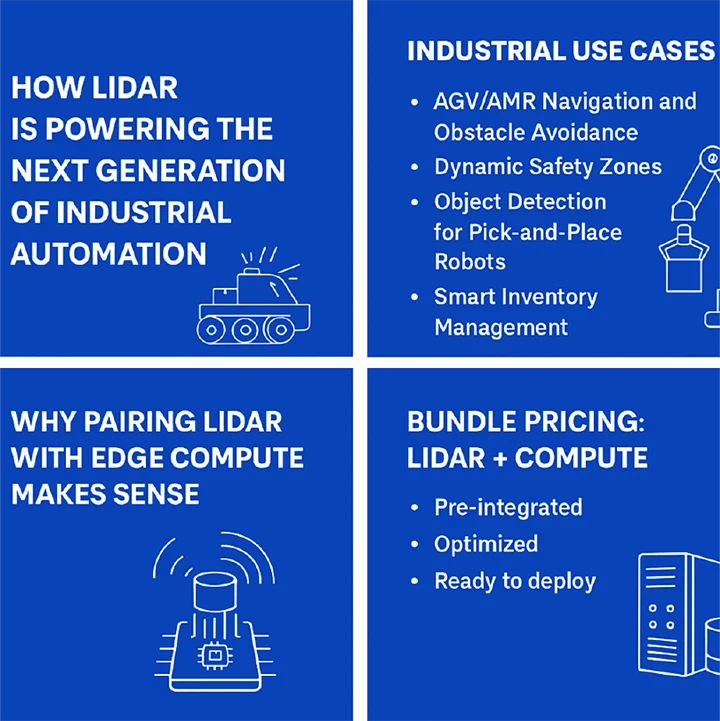

How Lidar is Powering the Next Generation of Industrial Automation

What is Lidar and Why It’s a Game-Changer for Industry

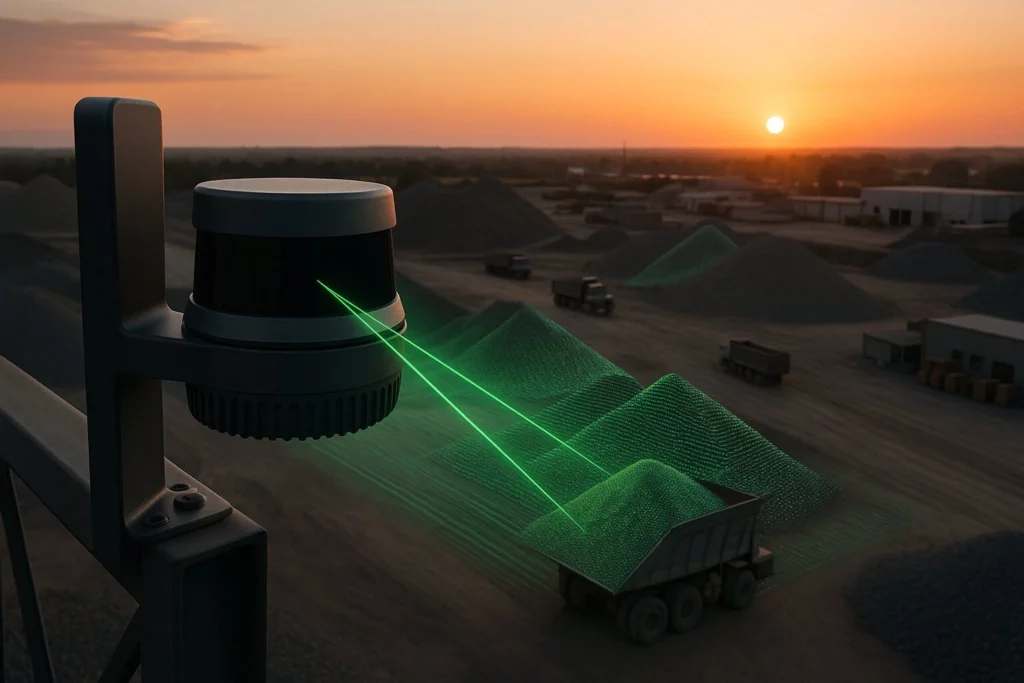

Lidar (Light Detection and Ranging) is no longer just for autonomous vehicles — it’s rapidly becoming a core sensing technology in modern industrial environments. By emitting laser pulses and analyzing their reflections, Lidar creates precise, real-time 3D maps of complex factory floors, warehouses, and workcells.

For industries dealing with automated material handling, safety zones, robotic navigation, and dynamic asset tracking, Lidar offers unmatched reliability — even in low-light, dust-prone, or high-traffic environments where other sensors fail.

Automated Guided Vehicles (AGVs) and Autonomous Mobile Robots (AMRs) depend on real-time perception. Lidar enables these machines to move safely, detect obstacles instantly, and reroute without manual input.

Fixed safety barriers are inefficient in flexible production lines. Lidar enables dynamic geofencing that adapts in real-time based on human presence, robot activity, or process changes.

With high-resolution 3D point clouds, Lidar provides depth perception and shape recognition for precision picking, bin picking, and automated assembly tasks.

Lidar can scan shelf height, object size, and pallet alignment with millimeter precision — reducing errors in inventory logging and enabling real-time spatial awareness in warehouses.

For bulk materials, Lidar can measure flow rates, detect jams, and ensure even loading — all without physical contact or moving parts.

Industrial environments demand real-time decision-making. When Lidar is paired with onboard GPU (e.g., NVIDIA Jetson) or embedded CPU modules, the system can run:

This eliminates the latency of cloud processing and avoids the downtime risk of connectivity loss.

To help integrators, OEMs, and operations managers deploy faster, we offer pre-integrated Lidar + compute bundles optimized for industrial automation. Each bundle includes:

You can save time and reduce risk by selecting a bundle that’s already tested and ready to deploy.

Before choosing your Lidar system, ask:

We help customers specify systems based on application — from factory automation to smart logistics and beyond.

Final Thoughts

Industrial automation is evolving rapidly, and perception is the foundation of autonomy and flexibility. Lidar is the sensor of choice for applications that demand 3D awareness, robust environmental performance, and low latency.

By bundling your Lidar solution with the right edge compute hardware, you eliminate guesswork, reduce deployment time, and move faster toward operational excellence.

We would be pleased to send you detailed information about our products or services.

Simply enter your details in the contact form below and we will get in touch with shortly.

CRATUS respects your personal information and keeps it safe. By sending this form, you consent to allow CRATUS to store and process your personal information as stated in our Privacy Policy.

One of our experts will be communicating with you shortly.